Breaking The Fiber Barrier: How Pretreatment Innovations Revolutionize High-Fiber Biomass Pelletizing With Advanced Biomass Pellet Machines

Introduction

High-fiber biomass, such as rice husks, banana stems, and agricultural residues, presents significant challenges in pellet production due to its rigid structure, low density, and high lignin content. These materials often lead to poor compaction, high energy consumption, and unstable pellet quality. However, advancements in biomass pellet machine technology and pretreatment methods are transforming these obstacles into opportunities, enabling efficient utilization of fibrous feedstocks for sustainable energy solutions.

The Challenge of High-Fiber Biomass

Fibrous biomass, like rice husks and banana stems, contains silica layers or coarse fibers that resist compression. For instance, rice husks’silicon-rich surfaces hinder molecular bonding during pelletizing, resulting in fragile, layered structures prone to breakage. Similarly, banana stems, with their high moisture content (often exceeding 60%) and bulky fibers, require specialized handling to achieve optimal densification. Traditional pellet machines struggle with these materials due to inadequate pressure distribution and insufficient fiber plasticity.

Revolutionary Pretreatment Technologies

1. Mechanical Size Reduction and Fiber Modification

Crushing and grinding are critical first steps. High-fiber materials like wood chips or straw are processed through hammer mills or crushers to reduce particle size below 3 mm, enhancing homogeneity and compressibility. For banana stems, studies show that shredding combined with screw extrusion significantly improves fiber plasticity by breaking down lignin bonds, enabling smoother compaction.

2. Steam Explosion and Thermal Conditioning

Steam pretreatment softens lignin at 200-300℃, increasing material viscosity and enabling better binding. This method reduces energy consumption during compression by up to 30% and improves pellet durability. For example, modified ring-die pellet machines integrate steam injection systems to preheat fibrous feedstocks, optimizing their moldability.

3. Chemical Additives and Binders

Natural binders like starch or carboxymethylcellulose (CMC) enhance pellet cohesion without compromising environmental benefits. Trials with gasified woody biomass char demonstrated that adding 2-5% starch increased pellet durability by 15% while maintaining low ash content.

4. Moisture Control and Drying Systems

High moisture levels (>12%) disrupt pellet formation. Advanced dryers integrated into pellet plants reduce moisture to 8-10%, ensuring stable compression. For instance, banana stem pellet machines achieve 2.76% final moisture through multi-stage drying, meeting stringent biomass fuel standards.

5. Smart Process Optimization

Machine learning algorithms now optimize parameters like steam-to-carbon ratios and compression force. A 2024 study showed AI-driven systems improved combustion efficiency by 20% in sugarcane bagasse pellets, minimizing trial-and-error adjustments.

Case Studies: Success in Action

Banana Stem Pelletizing: A specialized screw-extrusion machine designed for banana stems achieved a production rate of 358kg/h with 95.4% and 96.7% mechanical durability, proving the viability of tropical agricultural waste.

Rice Husk Solutions: By combining steam pretreatment with ring-die pellet machines, manufacturers reduced energy consumption by 25% while producing dense, low-ash pellets suitable for industrial boilers.

Future Trends in Biomass Pelletizing

AI-Integrated Pellet Plants: Real-time monitoring and adaptive control systems will further streamline production, reducing downtime and waste.

Eco-Friendly Binders: Research into lignin-based binders aims to eliminate synthetic additives, enhancing sustainability.

Modular and Mobile Systems: Compact, mobile pellet plants (e.g., 250–500 kg/h capacity) enable on-site processing in rural areas, reducing transportation costs.

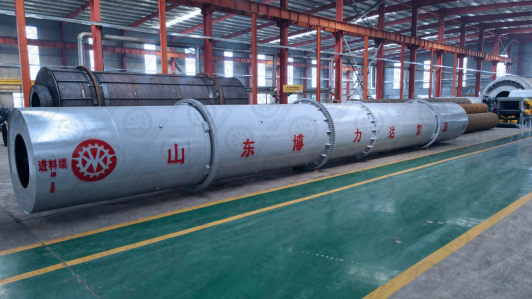

Spotlight: Shandong Bolida Machinery Co., Ltd.

A leader in biomass processing, Shandong Bolida Machinery Co., Ltd. specializes in innovative biomass pellet machines tailored for high-fiber materials. Their vertical ring-die pellet machines feature adjustable compression rollers and dual-layer molds, achieving 1.35 g/cm3 pellet density with minimal energy input. With ISO and CE certifications, the company offers turnkey solutions from design to after-sales support, serving clients globally in sectors like feed production and renewable energy.

Conclusion

The synergy of pretreatment technologies and advanced biomass pellet machines is unlocking the potential of high-fiber biomass, driving the transition to circular energy economies. By addressing fiber-specific challenges through innovation, industries can transform agricultural waste into high-value fuel, reducing carbon footprints and fostering rural development.