The Ultimate Guide to Biomass Wood Pellet Raw Materials and Their Applications

Introduction to Biomass Pellets

Biomass pellets, a renewable energy source, are produced by compressing organic materials like wood shavings, agricultural residues, and forestry waste into dense, uniform pellets. These pellets serve as a sustainable alternative to fossil fuels, reducing carbon emissions and promoting circular economies. Central to this process is the biomass pellet machine, a critical piece of equipment that transforms raw biomass into high-energy-density fuel.

Raw Materials for Biomass Pellet Production

The quality and efficiency of pellet production depend heavily on raw material selection. Below are the most common materials used:

1.Wood Shavings/Sawdust

Wood shavings and sawdust are the primary raw materials for biomass pellet production. Derived from timber processing, furniture manufacturing, or forestry residues, they offer high lignin content, which acts as a natural binder during compression. Ideal moisture content ranges between 10-15% for optimal pellet durability.

2.Agricultural Residues

Straw and Stalks: Wheat, rice, and corn stalks are abundant in agricultural regions. These materials require additional processing to reduce fiber length and moisture.

Rice Husks and Coconut Shells: Known for their high calorific value, these residues are widely used in Asia.

Bamboo and Tree Bark: These materials are durable and suitable for industrial-scale pelletizing.

3.Energy Crops

Fast-growing plants like switchgrass or miscanthus are cultivated specifically for bioenergy, offering consistent quality and high yield.

Why Wood Shavings Are the Preferred Choice

Wood shavings dominate biomass pellet production due to their unique advantages:

High Density: Raw wood has a density of 0.6–0.8 g/cm³, which increases to 1.1–1.5 g/cm³ after pelletizing, enhancing storage and transportation efficiency.

Low Ash Content: Clean wood shavings produce minimal ash (1–3%), reducing boiler maintenance.

Versatility: Compatible with most biomass pellet machines, wood shavings adapt to various pellet diameters (6–12 mm) and production capacities (1–4 tons/hour).

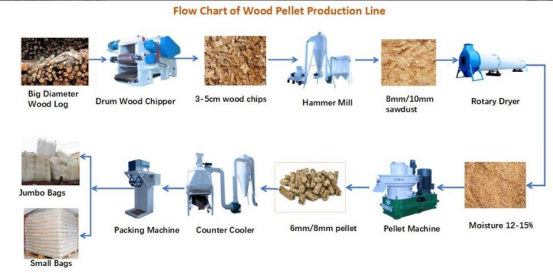

How Biomass Pellet Machines Transform Raw Materials

A biomass pellet machine employs mechanical pressure to extrude materials through a ring die, forming compact pellets. Key steps include:

Crushing: Raw materials are shredded into particles <5 mm.

Drying: Moisture is reduced to 10–15% using rotary dryers.

Pelletizing: High-pressure rollers compress the material into pellets. Advanced machines, like the YGKJ series, feature heavy-duty gearboxes and automated lubrication systems for stability and low energy consumption.

Cooling and Packaging: Pellets are cooled to room temperature and packed for distribution.

Applications of Biomass Pellets

Residential Heating: Clean-burning pellets replace coal in stoves and boilers.

Industrial Energy: Used in power plants and factories to reduce carbon footprints.

Commercial Use: Hotels and green buildings utilize pellets for centralized heating systems.

Environmental and Economic Benefits

Carbon Neutrality: Biomass pellets release only the CO₂ absorbed during plant growth.

Cost Savings: Pellet production from waste materials lowers fuel costs by 20–40% compared to coal.

About Shandong Bolidamech Machinery Co., Ltd.

A pioneer in biomass technology, Shandong Bolida Machinery Co., Ltd. (founded in 2013) specializes in manufacturing high-performance biomass pellet machines. Their flagship YGKJ series (e.g., YGKJ560, YGKJ700, YGKJ880,YGKJ1280) offers outputs of 1–15tons/hour, catering to diverse raw materials like wood shavings, straw, and rice husks.

Key Features:

Robust Design: Reinforced gearboxes and ISO/CE-certified components ensure durability.

Energy Efficiency: Reduced power consumption (90–250 kW) and automated operation lower production costs.

Comprehensive Services: The company provides installation, training, and a 1-year warranty, supporting clients globally.

For more details, please visit Shandong Bolida Machinery Co., Ltd.