The comprehensive crusher is composed of a machine base, knife rotor, upper and lower feeding mechanisms, feeding devices, and hydraulic buffering systems. It is mainly used for crushing and crushing materials such as wood log, construction templates, demolition materials, and templates.

The wood crusher mainly relies on impact energy to complete the task of crushing wood. The hammer type comprehensive crusher, when in operation, the motor drives the rotor to rotate at high speed, and the wood uniformly enters the chamber of the comprehensive crusher. The high-speed rotating hammer head impacts, cuts and tears the wood, causing it to be broken. At the same time, the gravity of the wood itself causes the wood to rush from the high-speed rotating hammer head to the baffle and sieve bar inside the frame. A sieve plate is installed at the lower part of the rotor, and the particles smaller than the sieve hole size in the crushed wood are discharged through the sieve plate. The wood larger than the sieve hole size is retained on the sieve plate and continues to be hit and ground by the hammer. It is mainly used for breaking round wood, small diameter wood, branches, branches, boards, Flat noodles, bamboo and other materials

Details:

|

The comprehensive crusher is composed of a machine base, knife rotor, upper and lower feeding mechanisms, feeding devices, and hydraulic buffering systems. It is mainly used for crushing and crushing materials such as wood log, construction templates, demolition materials, and templates.

The wood crusher mainly relies on impact energy to complete the task of crushing wood. The hammer type comprehensive crusher, when in operation, the motor drives the rotor to rotate at high speed, and the wood uniformly enters the chamber of the comprehensive crusher. The high-speed rotating hammer head impacts, cuts and tears the wood, causing it to be broken. At the same time, the gravity of the wood itself causes the wood to rush from the high-speed rotating hammer head to the baffle and sieve bar inside the frame. A sieve plate is installed at the lower part of the rotor, and the particles smaller than the sieve hole size in the crushed wood are discharged through the sieve plate. The wood larger than the sieve hole size is retained on the sieve plate and continues to be hit and ground by the hammer. It is mainly used for breaking round wood, small diameter wood, branches, branches, boards, Flat noodles, bamboo and other materials

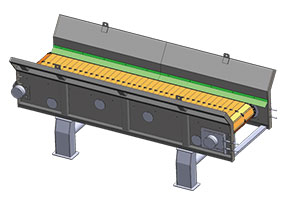

1. Feeding chain plate: all models adopt feeding chain plate, chain plate is Q345 steel plate.

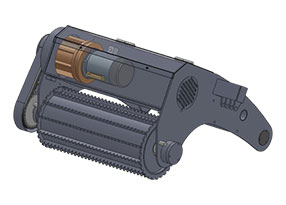

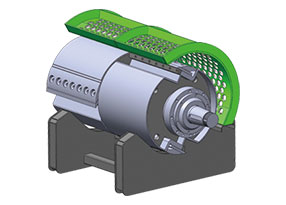

2. The main machine includes: main machine box, upper and lower feeding structure, spindle cutter roller, motor, etc.

3. Wearing parts: flying blade, fixed blade, bearing, triangle belt,etc.

4. The blade material is H13 steel .The hammer head is made of high manganese steel Mn13Cr2 or Mn13, and the surface is surfacing with YG8 carbide particles.

Raw material:

Wood slab

Bamboo

Branch

Waste wood board

Wood pallet

Wood

Details:

| Model | Power(kw) | Feed port size(cm) | After chipping size(mm) | Capacity(t/h) | Weight(t) |

| YMPJ1300-300 | 110+4+5.5+3+1.5 | 1300*300 | 30-110 | 6-10 | 8.5 |

| YMPJ1300-600 | 160+7.5+7.5+3+3 | 1300*600 | 30-110 | 12-15 | 11.5 |

| YMPJ1400 | 220+7.5+7.5++3+3 | 1400*600 | 30-110 | 15-20 | 14 |

| YMPJ1650 | 220+11+7.5+3+4 | 1650*600 | 30-110 | 18-25 | 16 |

| YMPJ2113 | 315+11+11+3 | 1100*530 | 30-110 | 15-25 | 20 |

| YMPJ2116 | 450+18.5*2+4+5.5 | 1250*700 | 30-110 | 40-60 | 45 |

Accessories introduction:

Feed Chain Conveyor

Feed Roller

Knife Rotor

Hydraulic Motor

Screen Mesh

Certification:

Our company has gained ISO9001-2000 Certification,CE Certification,SGS Certification patent etc.Products cover the environmental carbon, biomass,urban and rural environment,culture and other fields.There are five main series: the biomass compression molding equipment, garbage disposal equipment for urban and rural ,organic fertilizer equipment, Feeder Equipment and Environmental protection equipment .

FAQ:

Q: Are you manufacturer of trading company?

We are manufacturer, also with marketing department and R&D center.

Q: I am newer to biomass industry, how to design the suitable plant?

Do not worry about that. We already helped many beginners. We provide optimal project design according to every customer’s needs.

Q: Do you offer installation and training?

Yes. We can dispatch technicians to customers' site to help install equipment and train how to operate.

Q: How can you guarantee the after-sales service?

We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will be assigned to your site to solve problems timely. Also spare parts can be provided timely due to oversea warehouses.

Q: Are there some machines in my area I can observe?

Rotex Master have machines in many countries, if there are machines in your country, we can contact the customer to arrange a visit for you.

Q: Which kinds of raw material can be used for making pellets?

Sawdust (waste wood chips/shavings), other forest waste, agricultural straw, stalk, bamboo, peanut shells, rice husk, bagasse, alfalfa, palm fiber etc.

Q: What is the main process for making pellets?

Coarse Crushing Section(Splitter, Wood Chipper)—Drying Section—Crushing Section—Pelletizing Section—Cooling Section—Packing Section

Q: What is your work flow?

Inquiry—Quotation—Communication—Order Confirm & Payment Received—Production—Production Tracing & Inspection—Check Every Product—Book Vessel & Arrange Delivery—Documents Post/Telex Release—Customs Clearance—Arrange Delivery to Clients` Site—Discharge Goods—Arrange Installation & Debugging

Q: How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in 5 working days after signing the sales contract, the balance of 70% will be paid before the goods leave the factory.

(2) 30% deposit of the total amount to be paid by T / T 5 working days after signing the sales contract, the balance of 70% can be paid by L / C before the factory leave goods.

(3) We can negotiate specific payment terms with our client.

Q: How long is the delivery time?

For standard machines, that would be 25-30 working days; For non-standard machines and customized machines according to customers' specific requirements, it would be about 30 working days.

we work with the biggest freight forwarder in North China. if you need to appoint other freight measures, we can arrange them because we have rich experience and sufficient funds to handle.

Q: How about the documents after shipment?

After shipment, we wi ll send all original documents to you by DHL, including Bill of Lading, Commercial Invoice, B / L, and other certificates as required by customers.

Get An Instant Quotation

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Consuly Online Customer Service >