The mobile wood chipper is a more flexible chipping device produced by Rotexmaster. Diesel engine as driving force, can be traction outdoor production, high mobility, better mobile production. The mobile wood chipper Mainly used for crushing branches, trunks, bamboo, hemp pole, tobacco rods, straw and other materials. Crushed material size 1-3cm, thickness 5mm. The mobile wood chipper is the better choice for processing waste wood materials.

Details:

|

The mobile diesel wood chipper machine is a more flexible chipping equipment launched by our company. It uses a diesel engine as power and can pull outdoor production. It has strong mobility and better flow production effect. It is mainly suitable for crushing materials such as tree branches, trunks, bamboo, hemp stalks, tobacco stalks, straw, etc. After crushing, the material is 1-3cm thick and 5mm thick, making it a better choice for processing waste wooden materials.

Advantages of mobile wood chipper.

1.Powered by diesel engine, movable, highly flexible

2.It has a large feed inlet size to adapt to a wide range of materials.

3.The feed roller can be adjusted in both directions to prevent material blockage.

4.It use combination of fixed and moving knives to effectively control the fineness of materials

Raw material:

Wood Board Skin

Bamboo

Branch

Waste wood board

Wood pallet

Wood

Details:

| Model | Power KW | Feed port size CM | After chipping size MM | Capacity T/H |

| YPMJ40C | 40 | 300*200 | 300-110 | 1-2 |

| YMPJ216C | 130 | 545*280 | 300-110 | 3-5 |

| YMPJ218C | 220 | 710*360 | 300-110 | 6-10 |

| YMPJ1300C | 255 | 1300*600 | 300-110 | 8-12 |

| YMPJ1400C | 288 | 1400*700 | 300-110 | 15-20 |

| YMPJ2113C | 355 | 1100*530 | 300-110 | 20-25 |

Accessories introduction:

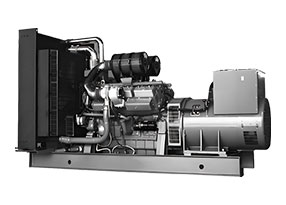

Diesel Generator

Hydraulic Motor

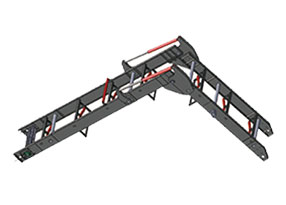

Folding Belt Conveyor

Screen Mesh

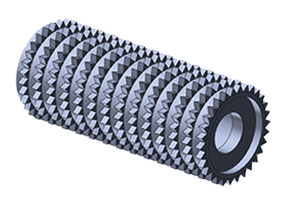

Feed Roller

Certification:

Our company has gained ISO9001-2000 Certification,CE Certification,SGS Certification patent etc.Products cover the environmental carbon, biomass,urban and rural environment,culture and other fields.There are five main series: the biomass compression molding equipment, garbage disposal equipment for urban and rural ,organic fertilizer equipment, Feeder Equipment and Environmental protection equipment.

FAQ:

Q: Are you manufacturer of trading company?

We are manufacturer, also with marketing department and R&D center.

Q: I am newer to biomass industry, how to design the suitable plant?

Do not worry about that. We already helped many beginners. We provide optimal project design according to every customer’s needs.

Q: Do you offer installation and training?

Yes. We can dispatch technicians to customers' site to help install equipment and train how to operate.

Q: How can you guarantee the after-sales service?

We have professional After-sales service center with experienced and skillful engineers. When problem of equipment occurs, our engineers will be assigned to your site to solve problems timely. Also spare parts can be provided timely due to oversea warehouses.

Q: Are there some machines in my area I can observe?

Rotex Master have machines in many countries, if there are machines in your country, we can contact the customer to arrange a visit for you.

Q: Which kinds of raw material can be used for making pellets?

Sawdust (waste wood chips/shavings), other forest waste, agricultural straw, stalk, bamboo, peanut shells, rice husk, bagasse, alfalfa, palm fiber etc.

Q: What is the main process for making pellets?

Coarse Crushing Section(Splitter, Wood Chipper)—Drying Section—Crushing Section—Pelletizing Section—Cooling Section—Packing Section

Q: What is your work flow?

Inquiry—Quotation—Communication—Order Confirm & Payment Received—Production—Production Tracing & Inspection—Check Every Product—Book Vessel & Arrange Delivery—Documents Post/Telex Release—Customs Clearance—Arrange Delivery to Clients` Site—Discharge Goods—Arrange Installation & Debugging

Q: How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in 5 working days after signing the sales contract, the balance of 70% will be paid before the goods leave the factory.

(2) 30% deposit of the total amount to be paid by T / T 5 working days after signing the sales contract, the balance of 70% can be paid by L / C before the factory leave goods.

(3) We can negotiate specific payment terms with our client.

Q: How long is the delivery time?

For standard machines, that would be 25-30 working days; For non-standard machines and customized machines according to customers' specific requirements, it would be about 30 working days.

we work with the biggest freight forwarder in North China. if you need to appoint other freight measures, we can arrange them because we have rich experience and sufficient funds to handle.

Q: How about the documents after shipment?

After shipment, we wi ll send all original documents to you by DHL, including Bill of Lading, Commercial Invoice, B / L, and other certificates as required by customers.

Get An Instant Quotation

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Consuly Online Customer Service >